Servis

Contact Us

Mechanically Sealed

Chemical Pumps

Chemical transfer pump

FRP casing, up to 350 m³/h

The ANSI/ASME B73.1 standardized centrifugal CFM pump series is designed to handle challenging applications. The components of the pumps in this are produced in high thickness to ensure maximum reliability.

Application

Sulfuric Acid (H2SO4), Hydrochloric Acid (HCl), Sodium Hypochlorite (NaOCl), Nitric Acid (HNO3), Caustic Soda (NaOH), Phosphoric Acid (H3PO4), Ferric Chloride (ZnCl2), etc.

Construction

The parts in contact with the liquid are made of thermoplastic block, the body (Fiberglass reinforced vinyl ester resin) and the gaskets are made of (EPDM, FPM, FFKM) material.

Performance Data

Flow

m³/h

350

Pressure

mWc

5-72

Motor

kW

1,1 - 37

Speed

rpm

950 - 1150 - 1450 - 1750 - 2900 - 3500

Operating Temperature

°C

-20 / +110

Application

Close Couple

Impeller

Semi-open

Construction Material

Chemical transfer pumps are manufactured from materials with high chemical and mechanical resistance such as PP, PE, PVDF, FRP.

PP

PE-UHMW

0/+90 °C

-30/+90 °C

Polypropylene (PP) is a thermoplastic polymer used in a wide variety of applications. It has high mechanical and temperature resistance.

Ultra-high molecular weight polyethylene (UHMWPE, UHMW).

It provides very high chemical and mechanical resistance.

PVDF

-20/+120 °C

-20/+120 °C

FRP

Polyvinylidene difluoride (PVDF) is a thermoplastic fluoropolymer.

PVDF is a specialty plastic used in applications requiring resistance to solvents, acids and hydrocarbons.

Fiber reinforced plastic (FRP; Fiber reinforced plastic) is a composite material made from a polymer matrix reinforced with fibres.

It is used in processes requiring mechanical and chemical resistance.

Processes

-

strong acids

-

ionic, salt solutions

-

halogenated compounds

-

hydrocarbons

-

aromatic solvents

-

aliphatic solvents

-

oxidants

-

bases

Applications

-

chemical processing

-

electricity, batteries and electronic components

-

construction and architecture

-

health and pharmacy

-

biomedical research

-

nuclear

-

petrochemical, oil and gas

-

food, beverage processing

-

water, wastewater management

Construction

01

The pump body made of high-thickness FRP provides optimum mechanical strength and chemical resistance without the need for metal armouring.

02

Semi-open centrifugal impeller.

03

The shaft sleeve is made of FRP or PE-UHMW and is produced as a one piece component, completely covering the part of the steel shaft in contact with the process fluid.

04

Single row radial bearing.

05

Shaft made of 42CrMo4 Carbon steel (special alloy on request), designed to support torsional and radial forces; Protected by a precision machined shaft sleeve made of FRP or PE-UHMW.

06

Intermediate adapter made of cast iron. A unique part designed to separate the electric motor from the main pump.

07

S235JR-EN1025 or SS316 chassis.

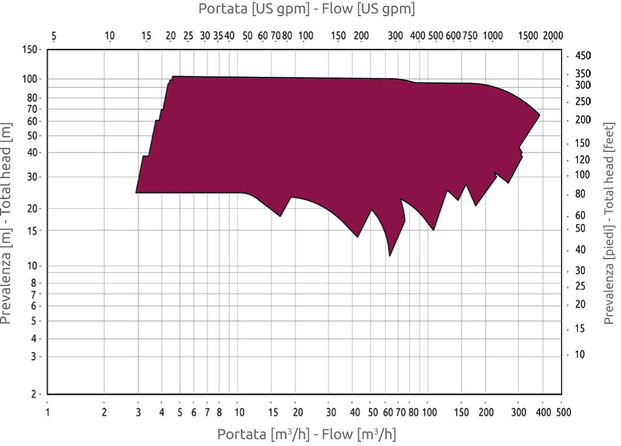

Performance Curves

1450 rpm - 50 hz

1750 rpm - 60 hz

2900 rpm - 50 hz

3500 rpm - 60 hz

Mechanical Seal

The elastomeric bellows seal is a mechanical seal designed for moderately corrosive, clean and not extremely hot liquids. It consists of static and rotating rings made of SiC; The spring and armor are made of SS316 and are not in contact with the process fluid. Elastomeric bellows are made of EPDM or FPM. This seal is available in external (B6E – B6EC), internal (B6I – B6IC – B6IH) and double flush (B6EDF – B6EDFC) types.

PTFE bellows seal is a mechanical seal designed for highly corrosive fluids and high temperatures. It has static and rotating rings in three different combinations (SiC-SiC, SiC-Al2O3, Al2O3-PTFE-C); It has PTFE bellows, springs and SS316 armor that does not come into contact with the pumped liquid. This seal is available in external (JRS – JRS1 – JRA) and double flush (JR2S – JR2S1 – JT2P – JR2A) types.

The elastomeric O-Ring seal is a mechanical seal suitable for moderately corrosive, clean and not extremely hot liquids. It consists of static and rotating rings in two different combinations (SiC-SiC, Carbon-graphite-SiC); bow and armor are Hastelloy C276. The O-ring is made of EPDM or FPM. This gasket is available in internal (UMG – UMS) and double flush (UM2G – UM2S) types.

Special Solutions

Screwless Impeller System

(D) impeller lock system

(C) nut

(B) washer

(A) Prevents the wheel from coming off the shaft if the wheel rotates against the direction of rotation during start-up

Shaft sleeve and impeller system

(C) shaft sleeve

(B) O-ring

(A) In case the shaft is damaged, it allows it to be replaced without dismantling the impeller to save on spare parts costs.